Modular Systems |

![]() This Page Under Construction

This Page Under Construction

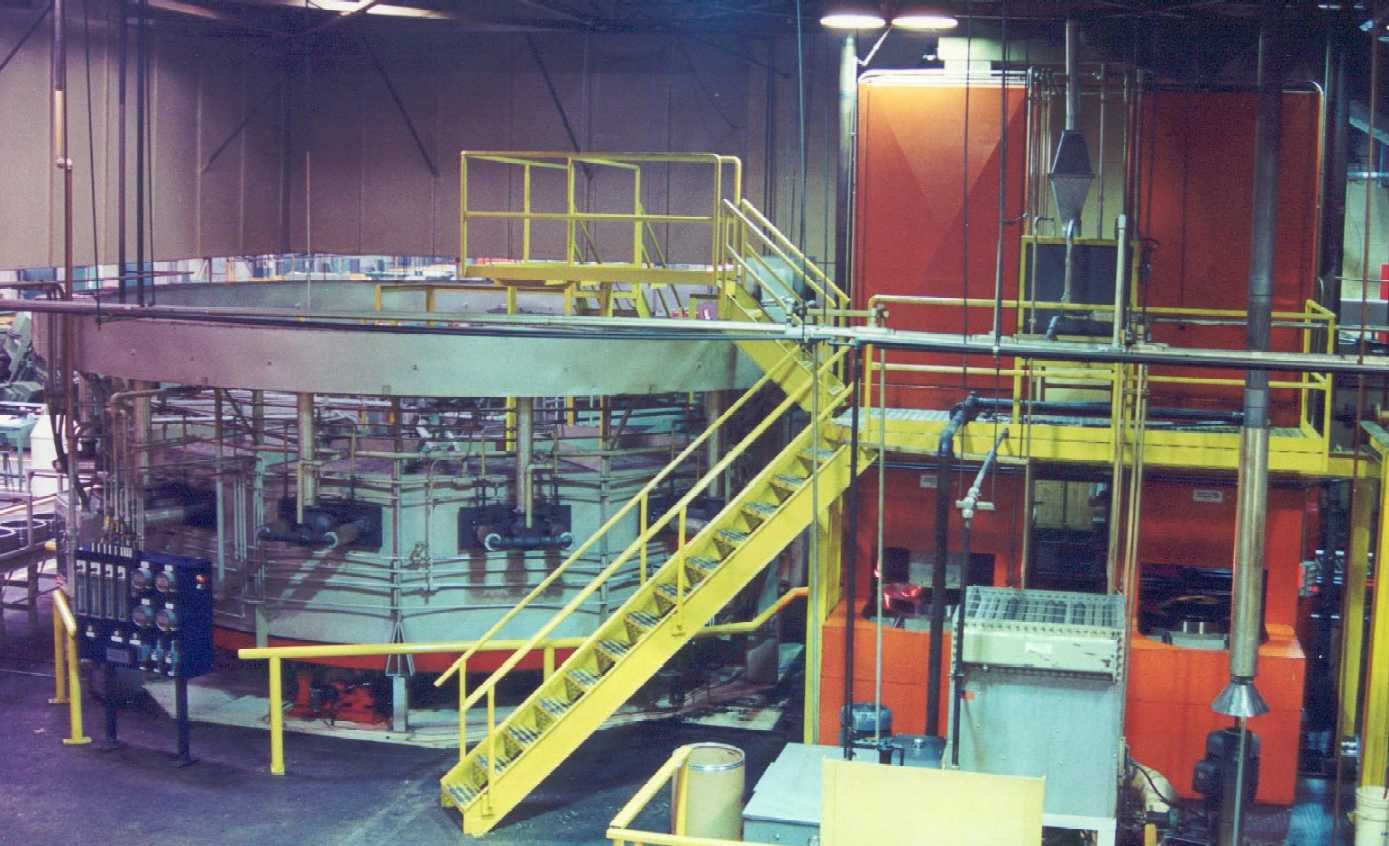

System with 10.5 ft Rotary Hearth Hardening and Tempering

Furnaces, 2 Servo Driven Quench Presses for 18.5" Max Part

Diameter, 2 Axis Furnace Loader, 4 Axis Gantry Robot, 2 Lane

Supply Conveyor, and 2 Lane Removal Conveyor with Spray Washer -

(2 Photos)

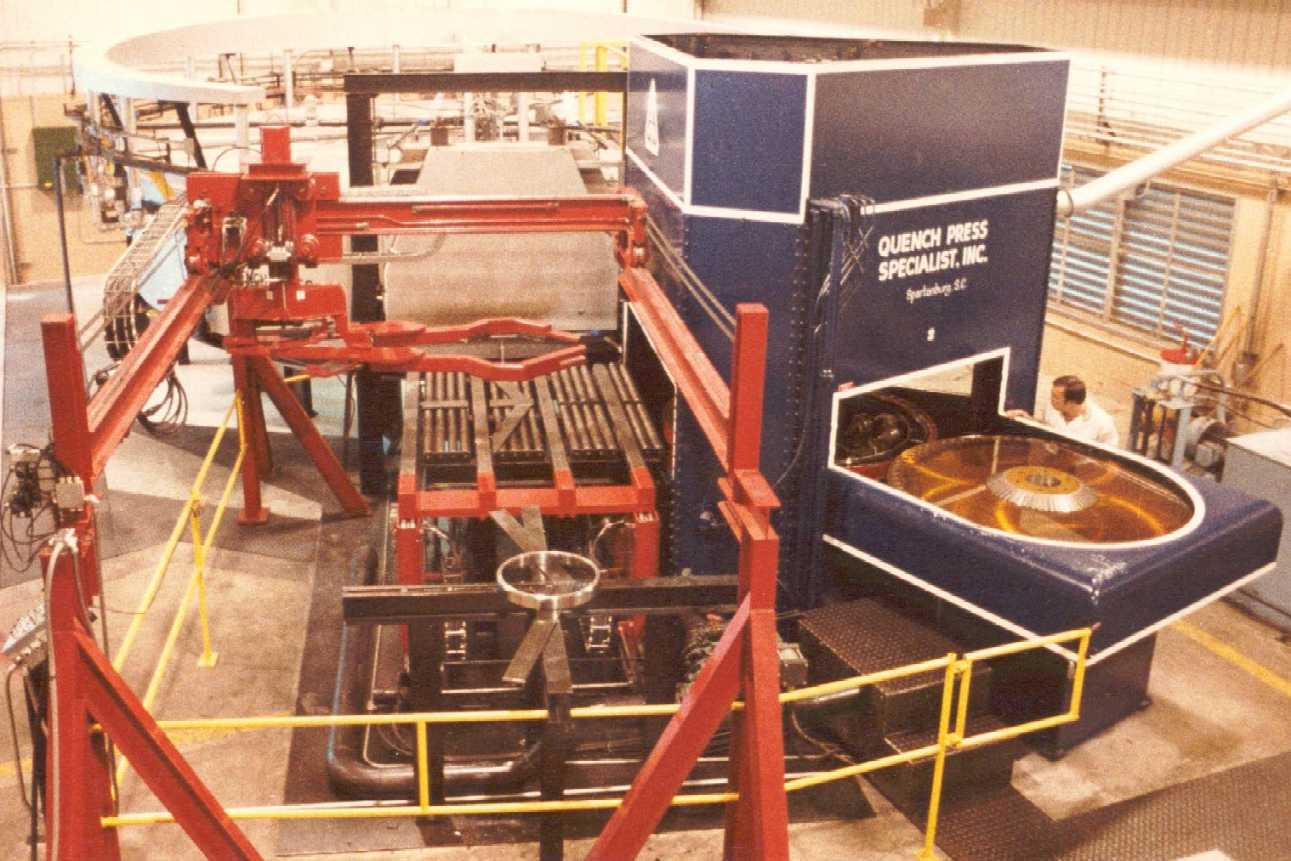

System with 22 ft

Rotary Hearth Hardening Furnace, Dual Ram Quench Press for 60"

Max Part Diameter, 2 Axis Furnace Loader, 4 Axis Gantry Robot

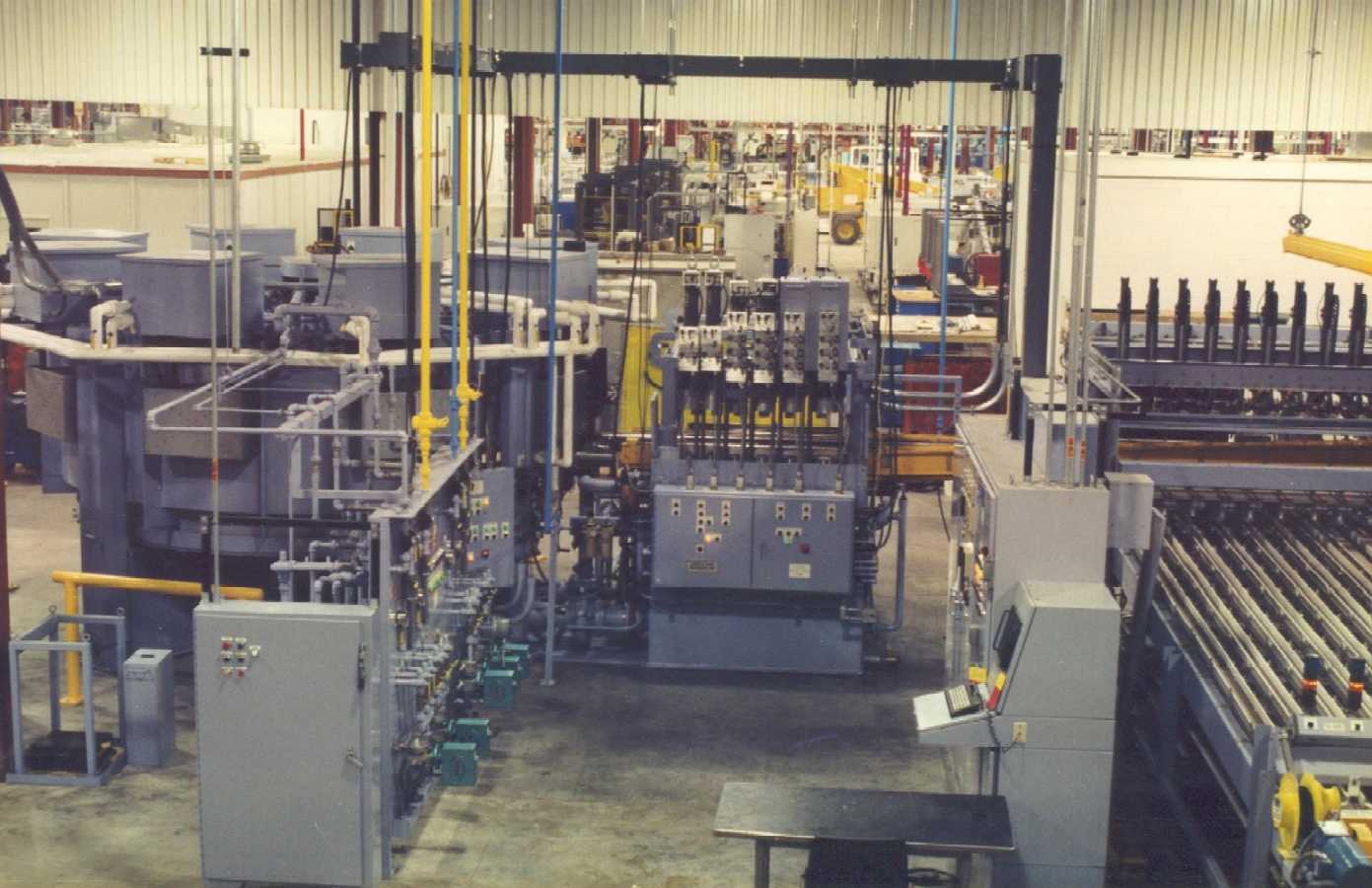

System with 12 ft

Carbonitriding Hardening Furnace, 6 Quench Presses, 22 Lane

Supply/Buffer Conveyor (unique part specific lanes), 22 Pick and

Place Robot for Loading each Hardening Furnace Supply (Queue)

Conveyor, 6 Lane HF Supply Conveyor, 2 Axis Lower Robot for

Loading the Hardening Furnace, 6 Gripper Upper Robot for Loading/Unloading

the Quench Presses and Lower Robot, and Removal Conveyor

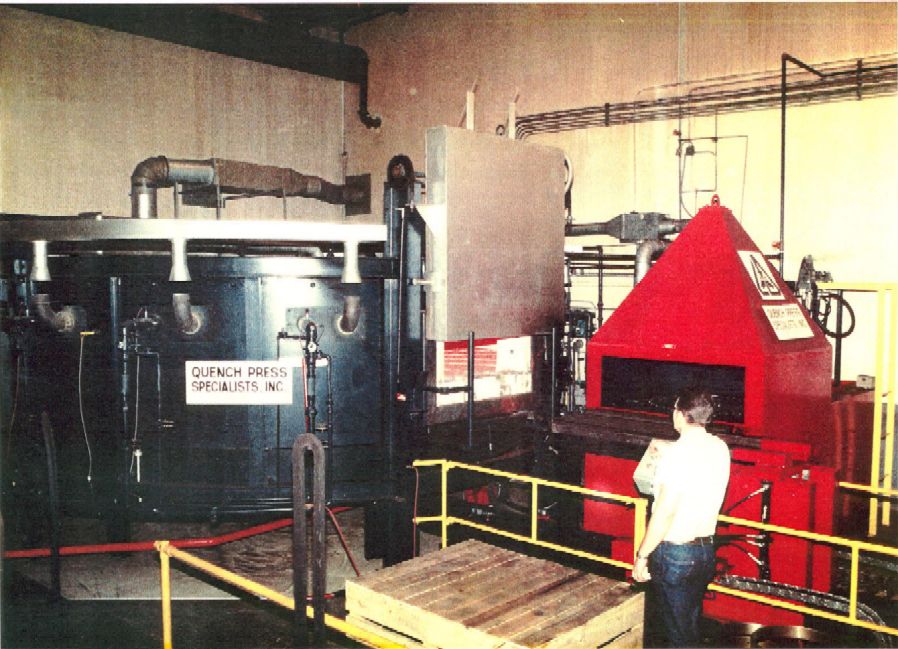

System with 21 ft

Hardening Furnace, 2 Dual Ram Quench Presses for Parts up 36",

Upper & Lower Robots for Loading the Hardening Furnace, Post

Quench Washers, 55 ft Tempering Furnace & Washer

System with 16 ft Rotary Hearth Hardening Furnace, Quench Press

for 40" Max Part Size, 2 Axis Furnace Loader

Home / QPS Advantage / Product Overview / Skid Systems / Modular Systems / Controls / Robots & Material Handling / Quench Presses / Quenchant Systems / Hardening Furnaces / Atmosphere Systems / Tempering Furnaces / Services & Support / Downloads / Careers / Contacts

| Copyright 2002 QUENCH PRESS SPECIALISTS INC. |

| Last modified: March 01, 2009 |