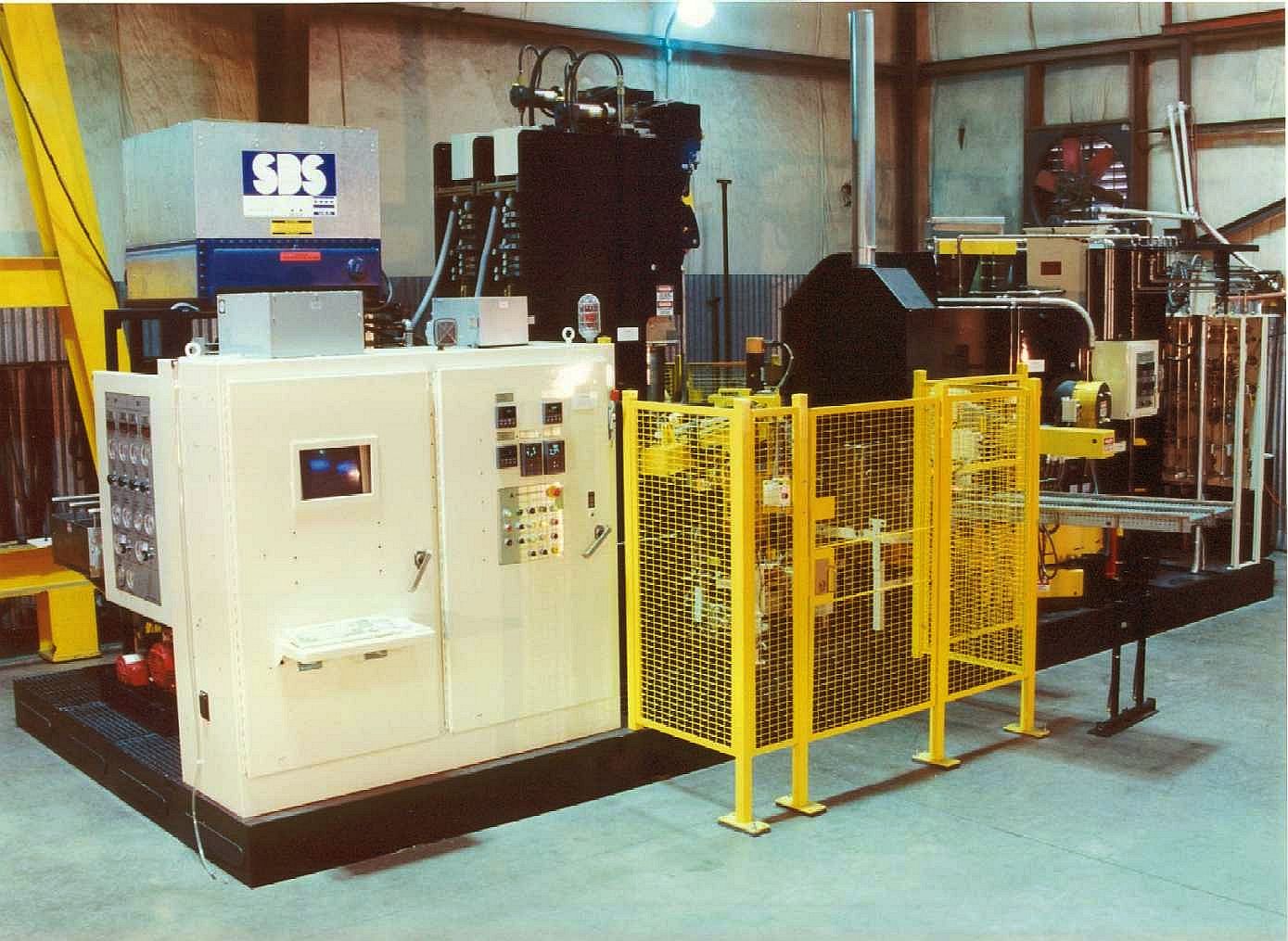

Skid System with 4' Rotary Hearth Furnace, 6" Toggle Quench Presses & Air/Oil Quenchant Cooling System - Front

Skid Systems |

Our skid mounted hardening systems are ideal for "in-line" heat treating automation. The standard systems are used for parts 2" to 10.5" diameter and accepts 2 lanes of parts loaded onto the supply conveyor. Pairs of parts are then loaded into the rotary hearth hardening furnace by the robot. The two parts making up the "pair" can be identical or different part numbers. After the parts have been properly heated to the hardening temperature, the same robot transfers the pairs of parts into the quench presses. The quench presses hold and/or form the parts, while a metered and directed flow of quenchant quickly cools the parts resulting in a high as-quenched hardness. Once the parts are quenched they are automatically ejected from the Quench Presses and transferred to the removal conveyor where the parts are typically washed. Parts then can be removed from the end of the removal conveyor or conveyed to an optional tempering furnace.

Superior quality components and extensive failure mode testing make these systems highly reliable with a minimum of unscheduled down time. Systems with our universal tooling for rings can harden a variety of part sizes with the same dies. Only 2 sizes of dies need be used to cover a 2-10.5" diameter range, however 4 different die sets may be needed if both male and female styles are required. The accurate control and integration of the atmosphere system, the application of heat inside the hardening furnace, the temperature uniformity in the hardening furnace, robot gripping techniques, quench press tooling design, and the application of the quenchant to the parts all act together to allow these systems to harden parts with consistent shape, size, and mechanical properties.

The following equipment and options are available for Skid Systems:

Below are images from some of the skid systems we have made.

Skid System

with 4' Rotary Hearth Furnace, 6" Toggle Quench Presses

& Air/Oil Quenchant Cooling System - Front

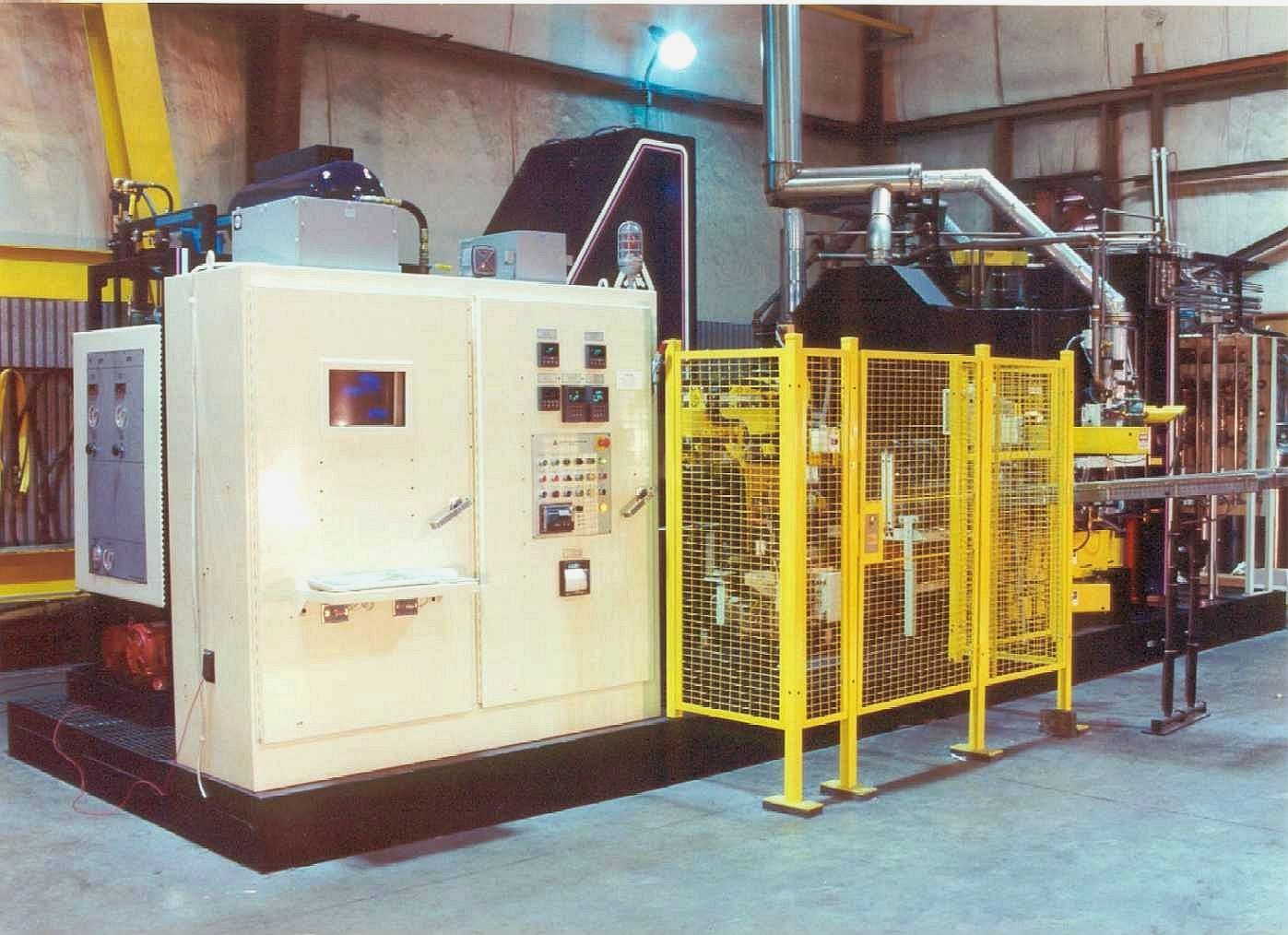

Skid System

with 4' Rotary Hearth Furnace, 6" Toggle Quench Presses

& Air/Oil Quenchant Cooling System - Back

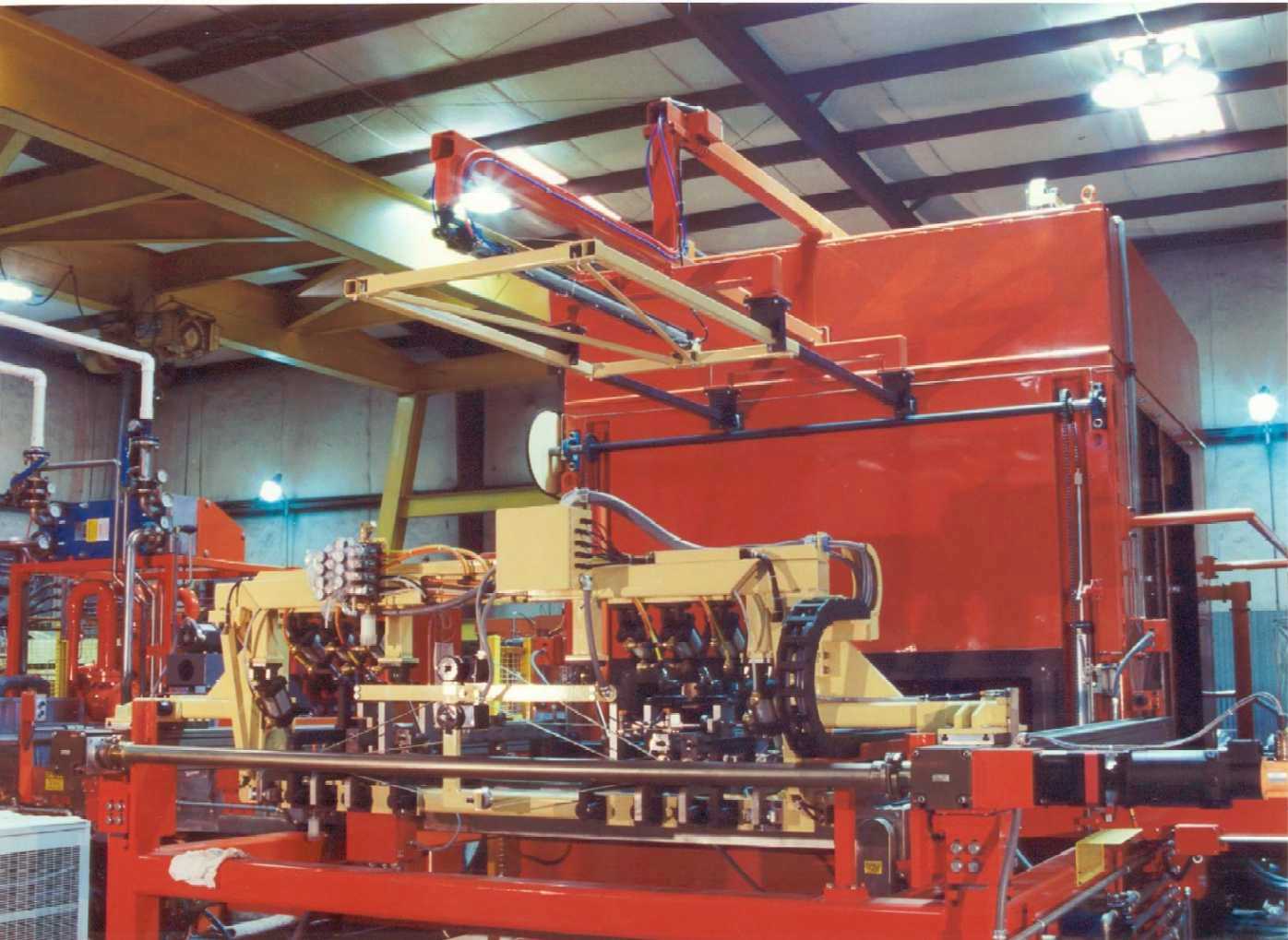

Skid System

with 5' Rotary Hearth Furnace, Universal Die Toggle Quench

Presses & Water/Oil Quenchant Cooling System

Skid System

with 5' Rotary Hearth Furnace, Universal Die Toggle Quench

Presses & Air/Oil Quenchant Cooling System

Skid System

with Gas Heated 5' Rotary Hearth Furnace, Direct Acting Plug-Type

Quench Presses & Water/Oil Quenchant Cooling System

Skid System

with 10' Rotary Hearth Furnace, Direct Acting Multiple Ram Quench

Presses & Water/Oil Quenchant Cooling System

Skid System

with 16' Rotary Hearth Furnace, Universal Die Toggle Quench

Presses & Water/Oil Quenchant Cooling System

Skid System Temper

Furnace & Loader

Home / QPS Advantage / Product Overview / Skid Systems / Modular Systems / Controls / Robots & Material Handling / Quench Presses / Quenchant Systems / Hardening Furnaces / Atmosphere Systems / Tempering Furnaces / Services & Support / Downloads / Careers / Contacts

| Copyright 2002 QUENCH PRESS SPECIALISTS INC. |

| Last modified: March 01, 2009 |